In the dynamic business world, where innovation and vision go hand in hand, few leaders truly stand out. Among these remarkable individuals is Gregor Brajovic, a multifaceted professional who has seamlessly navigated the realms of athletics, law, and entrepreneurship. With a remarkable journey spanning continents and an impressive repertoire of expertise, Gregor has emerged as a beacon of inspiration for aspiring business leaders worldwide. As the CEO of KraftPal Technologies, Gregor has leveraged his diverse background to spearhead transformative initiatives within the pallet industry, revolutionizing supply chains and leaving an indelible mark on the business landscape.

“As a professional athlete and a fully qualified lawyer, I have always sought to push boundaries and challenge the status quo,” Gregor Brajovic explains. “When I saw the environmental impact and inefficiencies caused by traditional wooden pallets, I knew there was an opportunity to make a significant difference.”

The wooden pallet, a staple of material handling for over a century, has remained virtually unchanged since its inception. Heavy, unhygienic, and difficult to recycle, these pallets have become a major source of environmental damage. Gregor recognized this urgent need for a sustainable solution and embarked on a mission to transform the industry.

“It’s been an amazing 100 years of breakthroughs in material handling and logistics, except for one key component: the wooden pallet,” Gregor elaborates. “We needed a pallet that was not only lighter and more eco-friendly but also adaptable to the demands of modern supply chains.”

With unwavering determination, Gregor and his team at KraftPal Technologies developed the revolutionary KraftPal Corrugated Cardboard One-Way Pallet. Designed for one-way use, these pallets address the environmental concerns associated with traditional wooden pallets.

“KraftPal Pallets is a game-changer in the industry,” Gregor proudly states. “They are 80% lighter than wooden pallets, significantly reducing fuel costs and carbon dioxide emissions. Moreover, being 100% corrugated cardboard, they are fully recyclable, offering a sustainable alternative for supply chains worldwide.”

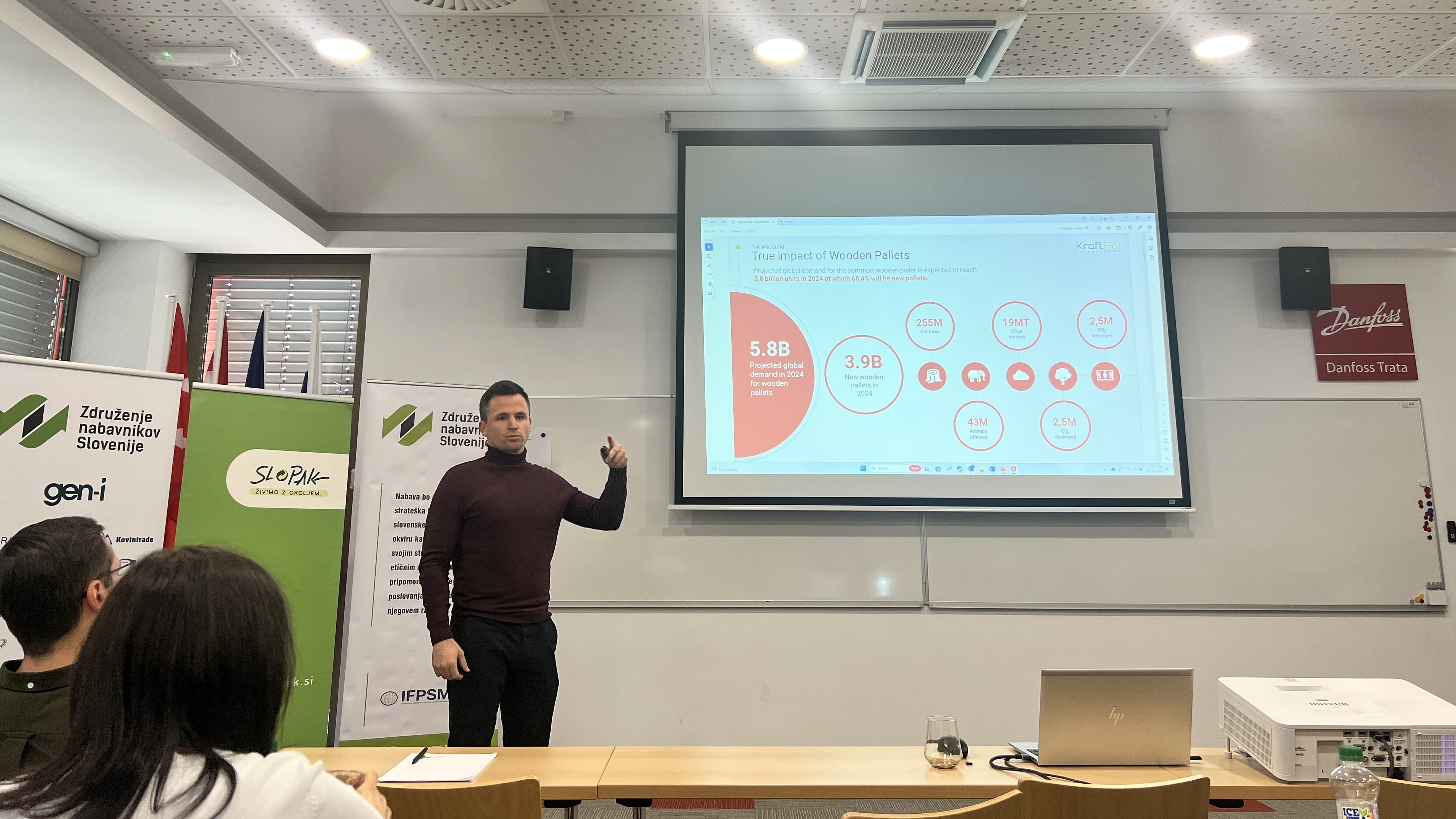

The environmental benefits of KraftPal Pallets are staggering. Over a third of the 5.8 billion wooden pallets produced annually are used for one-way purposes, contributing to landfill waste and deforestation. KraftPal’s innovative solution reduces this environmental impact while providing numerous other advantages.

“Not only are our pallets lighter and more eco-friendly, but they also offer superior performance,” Gregor adds. “They undergo heat treatment during production, making them 100% hygienic and compliant with ISPM-15 standards. Additionally, they possess moisture resistance in controlled environments and provide 80% better shock absorbency than wooden pallets.”

Gregor’s visionary leadership has positioned KraftPal Technologies at the forefront of the sustainable supply chain revolution. By reimagining the humble pallet, he has transformed the logistics landscape, emphasizing the importance of environmental responsibility and pushing the boundaries of what is possible.

“As business leaders, we have a responsibility to drive change and prioritize sustainability,” Gregor asserts. “Through KraftPal, we aim to inspire other companies to adopt eco-friendly practices and contribute to a better, greener future.”

Beyond his professional accomplishments, Gregor Brajovic’s impact extends far beyond the boardroom. Known for his philanthropic endeavors and dedication to social causes, he actively seeks to make a positive difference in the world.

“As I continue on this remarkable journey, I remain committed to giving back to society and supporting initiatives that uplift communities,” Gregor states. “We have a duty to create a better world, not just for ourselves but for future generations.”

Revolutionizing Production: The Power of the Palletonator

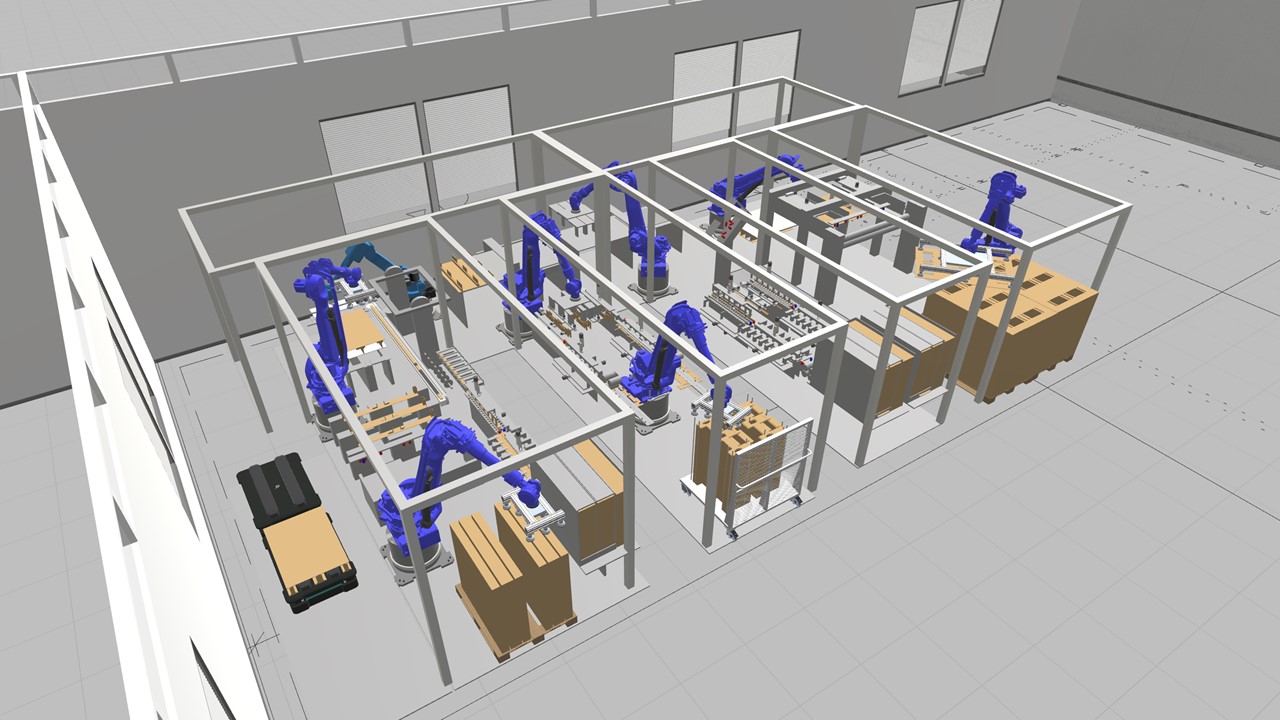

What’s even more impressive about KraftPal Corrugated One-Way Pallets is their unparalleled strength and production capabilities. With the ability to support a static load of four-and-a-half tons, these pallets are a testament to their unique, patented X-Frame construction. This exceptional strength is made possible by the revolutionary Palletonator, designed and developed in Slovenia to be the world’s most sophisticated automated production line.

“The Palletonator is a true game-changer in pallet manufacturing,” Gregor Brajovic explains. “Its cutting-edge technology and efficiency enable us to produce KraftPal pallets with remarkable speed and precision.”

Comprised of over 15,000 high-tech elements, each meticulously designed, the Palletonator boasts unparalleled capabilities. In a matter of seconds, it can produce a KraftPal pallet, and with millions of pallets manufactured each year, it has redefined the industry’s production standards.

“With the Palletonator, we have the flexibility to meet the unique needs of our customers,” Gregor states. “The production process can be fully customized, allowing us to create pallets that align perfectly with their specific requirements.”

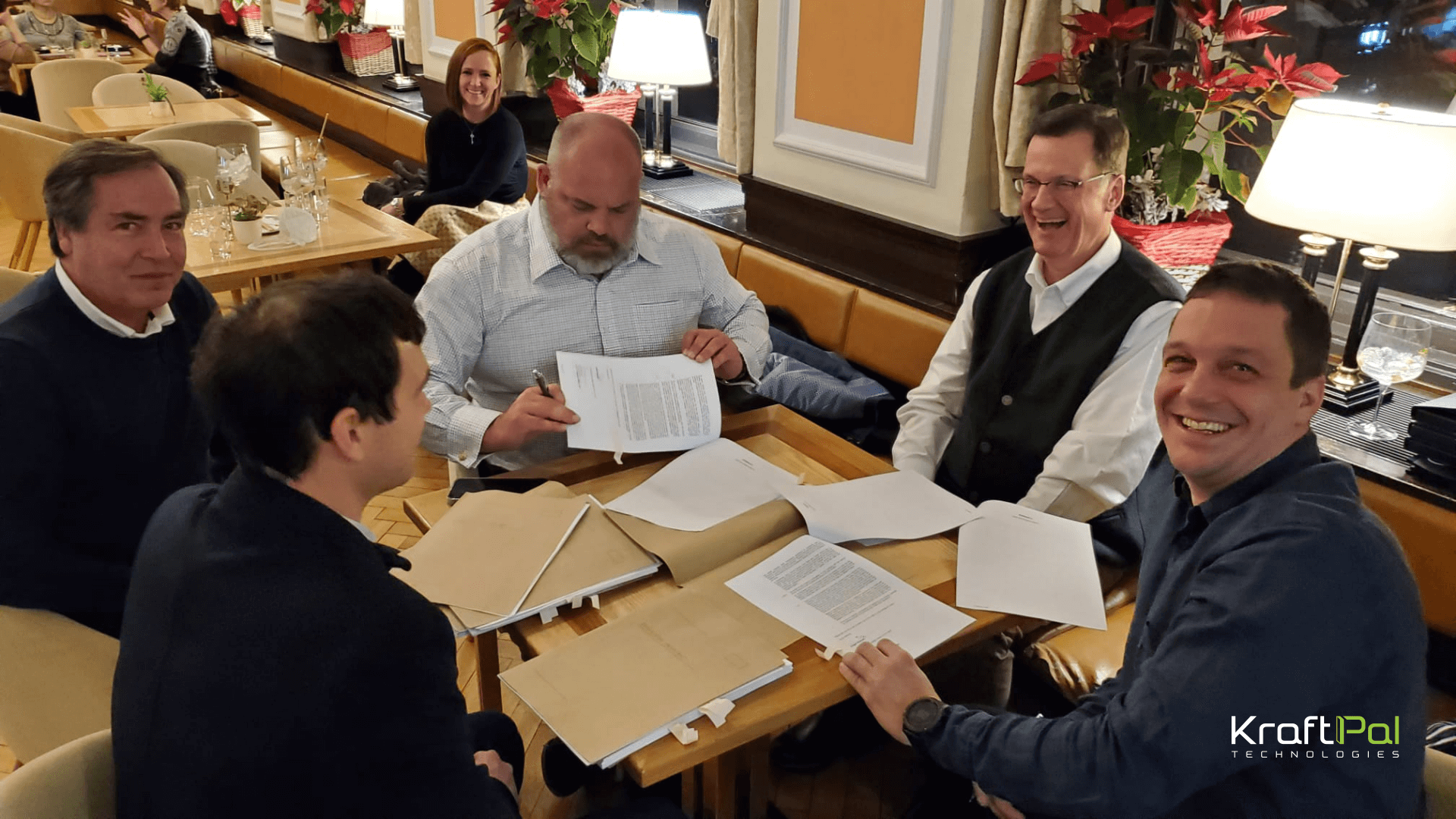

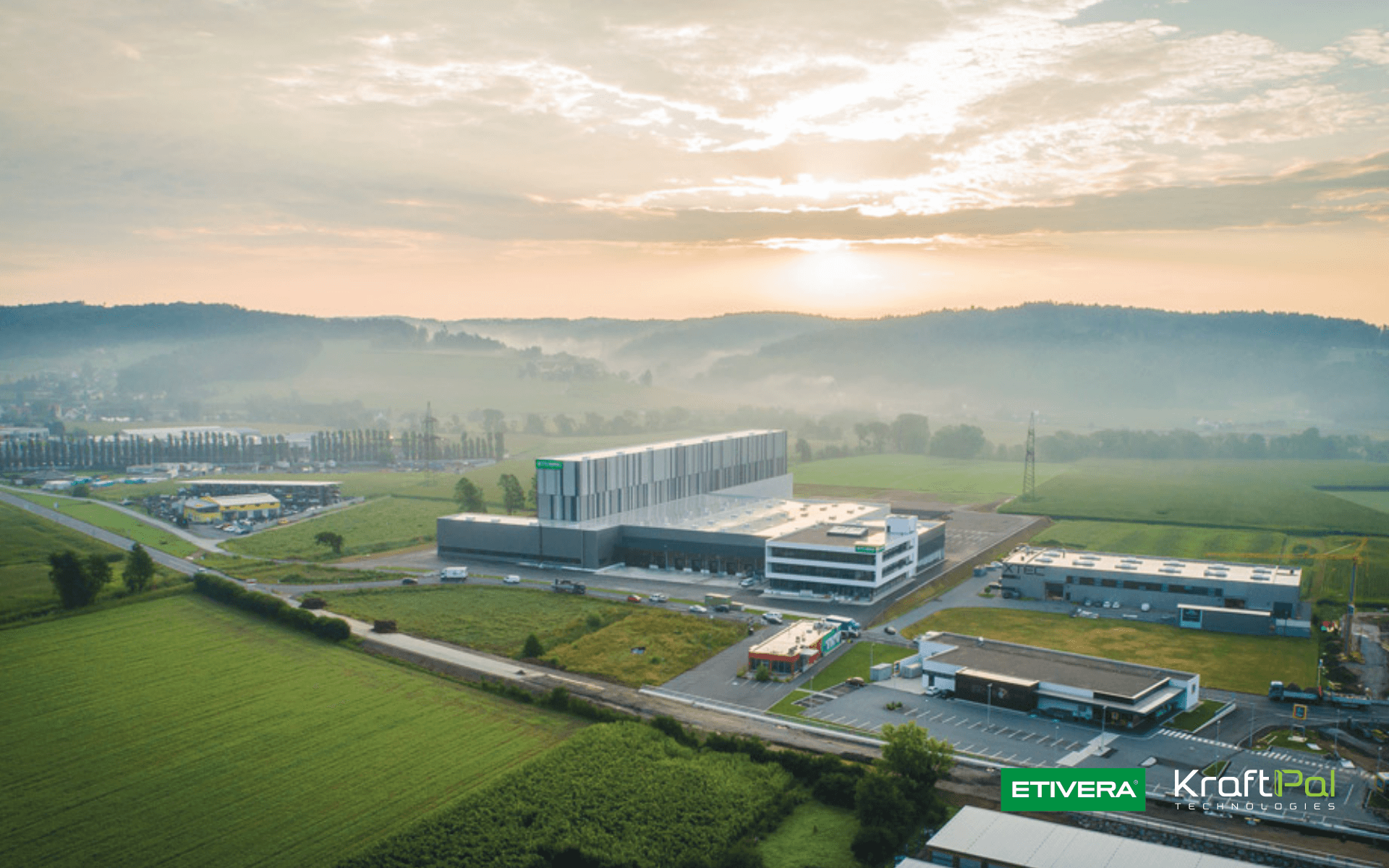

Pasaca Capital’s historic financial investment in KraftPal has paved the way for further expansion and innovation. By 2026, the company plans to build 60 fully operational Palletonators, marking a significant milestone in the history of pallet manufacturing. This ambitious undertaking will enable KraftPal to produce a staggering 90 million pallets per year, satisfying the global demand for the pallet that is reshaping the industry.

“Thanks to the support of Pasaca Capital, we are poised to revolutionize the supply chain on an unprecedented scale,” Gregor shares. “Our expanded production capabilities will allow us to meet the growing needs of businesses worldwide.”

One of the most remarkable aspects of switching to KraftPal Corrugated One-Way Pallets is the seamless transition it offers. Companies can embrace the future of modern pallets virtually overnight without requiring new equipment or extensive training.

“Making the switch from traditional wooden pallets to KraftPal is effortless,” Gregor highlights. “There’s no disruption to operations or logistical challenges. It’s a simple and effective solution that delivers immediate benefits.”

The 5th generation of the Palletonator stands as a testament to KraftPal’s commitment to innovation and efficiency. This automated, streamlined robotics pallet production line incorporates proprietary processes and patented technologies, setting new standards for the industry. With mass production capabilities in just seconds, high-volume orders can be fulfilled quickly and reliably, ensuring efficient logistics and cost savings for businesses.

“KraftPal offers more than just a pallet; we offer customized solutions,” Gregor emphasizes. “Whether it’s the size, shape, or specific application requirements, our team can tailor the pallets to meet the exact needs of our customers. We provide a comprehensive solution for efficient and sustainable logistics like customizable cardboard boxes.”

As KraftPal continues to revolutionize the supply chain, Gregor Brajovic’s visionary leadership and commitment to innovation drive the company forward. The future has indeed arrived, and it rests upon the foundation of KraftPal Corrugated Pallets — a testament to the transformative power of technology, sustainability, and a relentless pursuit of excellence.

Building a Sustainable Future: KraftPal’s Commitment to Innovation and Sustainability

Since its inception, KraftPal Technologies has been fueled by a relentless pursuit of innovation and sustainability. With a firm belief in the power of research and development, the company has invested significant resources in establishing state-of-the-art centers dedicated to pushing the boundaries of what is possible. Gregor Brajovic, CEO of KraftPal Technologies, sheds light on the company’s commitment to cutting-edge research and design.

“From day one, our focus has been on continuous research and development,” Gregor affirms. “We recently opened two design centers in Slovenia and California to facilitate joint projects with our customers and ensure compliance with international standards.”

KraftPal’s primary research and development center boasts advanced technology tailored explicitly for product development, global paper supplier verification, and corrugated board. With an in-house engineering office and a dedicated production team for mechanical engineering, the company ensures the highest standards are met throughout the design and manufacturing process.

“The Palletonator, with its intricate design consisting of over 15,000 components, demands meticulous attention to detail and adherence to strict internal standards,” Gregor explains. “We utilize FSC-certified corrugated cardboard, ensuring that our pallets meet the highest quality standards while maintaining our commitment to sustainability.”

Innovation is deeply ingrained in the DNA of KraftPal Technologies. The company embraces a culture of constant improvement, always seeking better solutions and adapting to evolving realities.

“To stay ahead of the curve and remain successful, we must constantly evolve and adapt,” Gregor states. “Our dedication to innovation is one of the strongest core competencies of our company, allowing us to lead the way in sustainable pallet solutions.”

KraftPal’s dedication to innovation and sustainability has not gone unnoticed. The World Packaging Organization recognized the company’s groundbreaking achievements by awarding them the prestigious “Packaging Excellence Award 2021” for their remarkable innovation.

“At KraftPal, we are proud to receive recognition for our commitment to excellence and sustainable solutions,” Gregor expresses. “It serves as a testament to our team’s hard work and dedication.”

In an era where environmental consciousness is paramount, KraftPal acknowledges the growing demands for sustainability within supply chains. The company actively collaborates with businesses, offering its expertise to help reduce carbon footprints and achieve net-zero goals.

“We understand that consumers and legislators in the EU are increasingly calling for sustainable supply chains,” Gregor acknowledges. “KraftPal is here to support companies in their quest for sustainability, providing cost-effective solutions that deliver substantial benefits.”

The benefits of adopting KraftPal Corrugated One-Way Pallets are vast. From reduced fuel costs and lower CO2 emissions (up to 80% per pallet) to simplified logistics and improved downstream efficiencies, KraftPal offers a comprehensive solution that aligns with the needs of today’s world.

“As the first cardboard pallet designed for the modern era, KraftPal is leading the way towards a sustainable future,” Gregor affirms. “Our pallets are not only innovative and efficient but also eco-friendly, making them the ideal choice for businesses seeking to minimize their environmental impact.”

The future arrives on a KraftPal pallet, where innovation and sustainability converge to reshape supply chains and pave the way for a greener, more sustainable world. As we celebrate the most inspiring business leaders of 2023, it is impossible to overlook the remarkable achievements and unwavering spirit of Gregor Brajovic. His journey from the world of sports to the intersection of law and business is a testament to the power of passion, resilience, and a relentless pursuit of excellence. With KraftPal Technologies at the forefront of the sustainable supply chain revolution, Gregor’s visionary leadership continues to shape the future of business, inspiring countless others to dream big and redefine the boundaries of success.

Whole article can be read on this link.